Today’s “ESPER Customer Stories” Q&A is with Sam Jackson, Director at sample & hold – a 3D scanning company focused on the creative media sector.

After using ESPER boxes, Sam is less stressed about the reliability of his multi-camera setup and feels an improvement in productivity.

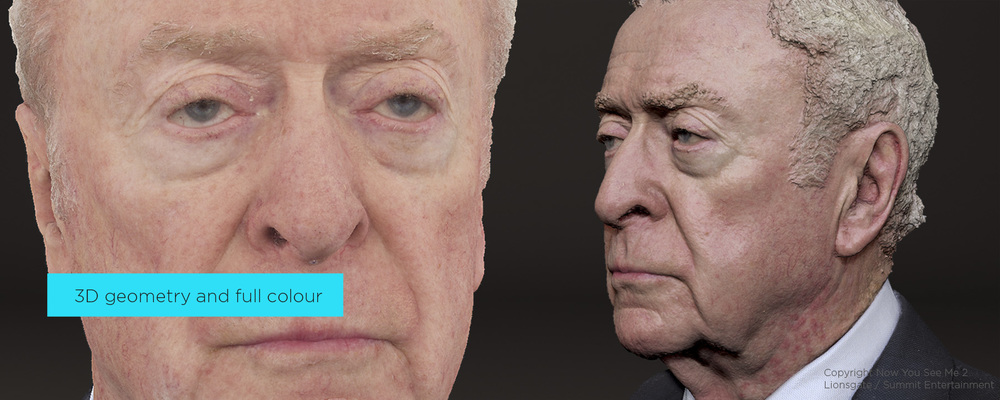

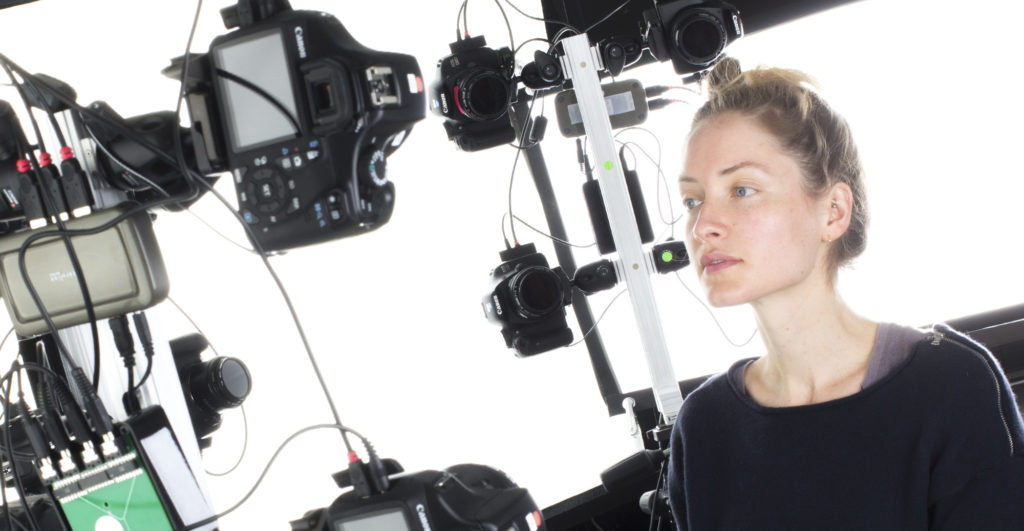

60 cameras 3d scanning array by sample & hold using ESPER TriggerBox and ESPER PowerBox

Here’s Sam’s story:

Tell us about sample & hold

Chris (Cornish) and I set up Sample & Hold back in 2011.

We both have over 10 years experience working on 3D scanning projects so our aim was to pool our skills and create a company that produces the highest quality 3D data using the latest 3D capture technology.

We’ve worked on everything from Hollywood films to AAA games and we’ve scanned everything from horses to Michael Caine.

I understand originally you built your own camera sync and power units?

From the outset, we knew we needed dependable hardware to power and trigger our multi-camera scanning setup.

So, we ended up building our own multi-camera sync and power boxes in-house, which we used for quite a while. This was before ESPER’s boxes were available, I must add!

What led you to use ESPER boxes?

It’s fair to say that our boxes tended to be a little ‘flaky’.

We have a 60 camera head 3D scanning rig and an 80 camera body. As a result, we seemed to be spending as much time fixing sync and power issues as doing the scans. Which when you’re working against the clock and it’s your reputation on the line it becomes very, very stressful and a big problem.

So, switching to ESPER boxes was about improving reliability?

Completely. We’d heard good things about the ESPER trigger and power boxes so we decided to give them a try.

Anything that meant we’d spend more time scanning and less on fixing sync and power issues!

Did you have any reservations about switching to ESPER kit?

Initially, yes. We had genuine concerns about reliability.

From our own experience, we knew that the theory of building the boxes was fairly simple. However, implementing that theory to make a 100% reliable, ‘non-flaky’ product is really tough!

Ultimately, we can spend more time producing quality scan data and less time fiddling with sync and power issues!

And how reliable have the ESPER boxes been?

Using ESPER PowerBoxes and TriggerBoxes we can definitely feel an improvement in productivity.

Learn more about the ESPER TriggerBox and PowerBox.

More interviews: